Company News

The latest updates from our organization

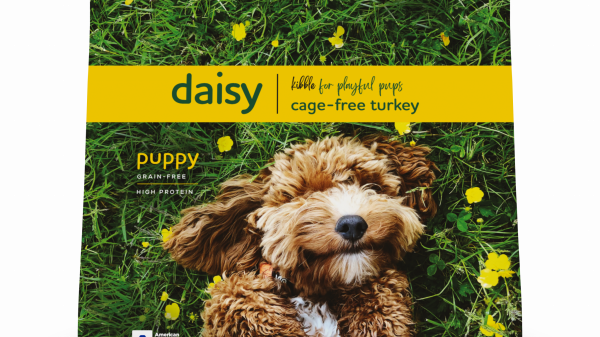

American Packaging Corporation Announces Another “Design for Recycle” Package

FOR IMMEDIATE RELEASE

American Packaging Corporation Announces Another “Design for Recycle” Package

A New Sustainable Offering for Pet Food and Treat Applications

Columbus, Wisconsin - American Packaging Corporation (APC), a leader in flexible packaging solutions, announces the commercial launch of another RE® Design for Recycle flexible packaging technology targeted at pet food products ranging from small pouches for pet treats to large bags (up to 38#) for pet kibble. This new technology joins a portfolio of packaging technologies in APC’s RE® sustainable packaging portfolio, that also includes Design for Compost, Circular Content, and Renewable Content, as well as several additional Design for Recycle film and paper options.

The breadth of products as well as the focus on quality and premiumization geared toward the pet market were definite considerations for this development. Conventional offerings tended to include multi-material laminates that could not be reused or recycled, and the goal was to develop packaging that was compliant with industry guidelines for recyclability and could be recycled where proper collection and sorting facilities exist. Transitioning from these complicated laminates to PE-based materials compatible with recycling required use of newer material offerings and process technologies. Ultimately, APC was able to optimize each package offering for appearance, shelf life, durability, manufacturability, and consumer functionality.

The technologies employed in the print web included both blown and oriented print webs as well as some more recent innovations providing even greater heat resistance which helped aid in improving the manufacturing operating window for these PE-based laminates. The sealants were also tailored for the application. These included compositions that offered low seal initiation points, options for moisture and oxygen barrier properties, as well as grease resistance, and product durability. Of particular concern was proper selection of the print and sealants that provided the drop and durability required for the larger format bags.

To read the full article, click here.