Preformed Pouches & Bags

Suiting a range of flexible packaging requirements

A wide variety of capabilities in manufacturing preformed bags and pouches in a robust selection of structures. We’re able to incorporate extrusion laminations, adhesive laminations and coated structures using our rotogravure and flexographic printing capabilities.

Below is a list of APC's types of Preformed Pouches and Bags, which include side heat seal pouches, stand-up pouches, side-gusseted bags, flat-bottom pouches and shaped pouches along with many options such as registered matte and gloss coatings, and a variety of open and reclose features.

TYPES OF PREFORMED POUCHES AND BAGS

Preformed Pouches

- Two Side Heat Seal Pouch - fold on bottom, sealed on sides

- Three Side Heat Seal Pouch

- Doyen/Mitre/K-Seal/Plow Style Stand-Up Pouch

- Box Style Pouch

- Fin Seal/ Lap Seal Pillow Pouch

Preformed Bags

- Box Style Bag

- Quad Seal Side Gusset - Pinch Bottom

- Quad Seal Side Gusset - Fold Over Glue

- Quad Seal Side Gusset - Bottom Open

Options for Preformed Pouches & Bags

- Design for Recycle Structures

- Terminated and Non-Terminated Gussets

- Thumb Notches

- Inno-Lok® Resealable Closure

- Reclosable Zippers - Press to Close, Pocket Zipper

- Hook & Hook Closure

- Laser Scoring

- Laser & Mechanical Perforations

- Handle Reinforcements

- Hang Holes and Tear Notches

- Pressure-Release Scoring

- Degassing Valve

- Unique QR Code

- Shaped Pouches

- Fitments

- Applied Labels or Booklets

APC CENTER OF EXCELLENCE CERTIFICATIONS

- OSHA VPP Star Worksite (Story City since 2003)

- ISO 9001:2015 Certified

- ISO 14001:2015 Environmental Certified

- GFSI: FSSC 22000 v.5.1 Certified

- SMETA 4-Pillar Audit (Sedex Member Ethical Trade Audit)

- Graphic Measures International (GMI) Certified

- ISCC+ Certified

- IMS Listed (Story City, Chili, Cedar City & Rochester)

- G7 Mater Certification (Columbus & DeForest)

- FDA DMF Maintained (Story City)

- Ecovadis Assessed (Corporate Wide)

- Supplier Leadership on Climate Transition Badge - Scope 3 (Corporate Wide)

- Carbon Disclosure Project Assessed (CDP) (Corporate Wide)

ENVIRONMENT HEALTH & SAFETY

At APC, protecting the environment and ensuring the health and safety of our employees is at the core of everything we do and every decision we make. Everyone in the APC family has a responsibility to ensure our operations and products meet applicable government and APC standards, always aligning with whichever is more stringent. Our goal is to prevent adverse environmental impacts by reducing waste and emissions and eliminating all preventable health impacts and injuries to our employees.

We’re committed to supplying safe products that exceed customer quality requirements.

- Flexographic Printing & Laminating Centers of Excellence (2)

- 103 West Broad Street

Story City, IA 50248

515-733-1400 - 1211 North 5300 West Cedar City, UT 84721

920-623-2291 - Rotogravure Printing & Laminating Center of Excellence

- 100 APC Way

Columbus, WI 53925

920-623-2291

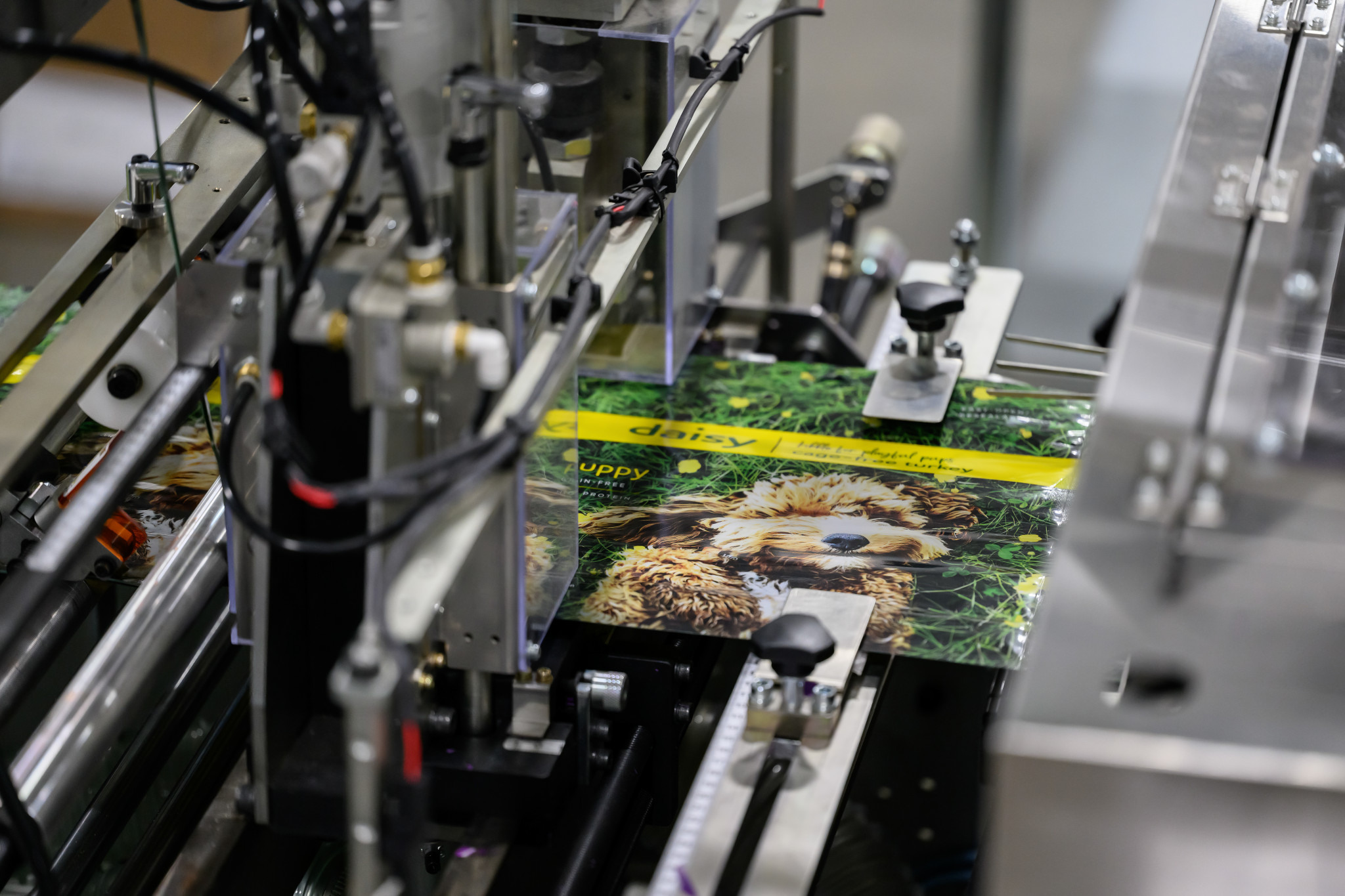

AUTOMATION

Ensuring high-performance production and quality assurance

APC’s Centers of Excellence also feature a full range of automated systems, including robotic material handling equipment, computerized slitting and rewinding equipment, and 100% defect detection systems. All these systems work together to make our operations as fast, efficient and precise as possible, resulting in quicker turnaround times, lower costs, minimal defects and higher overall quality for our flexographic printing and preformed bag and pouch customers.

At APC, we’re here to serve your unique requirements for flexographic printing of flexible packaging and custom preformed bags and pouches, no matter the size or scope. Our team is ready to guide you through the entire process to ensure the perfect flexible packaging solution.